Mesothelioma & Asbestos Exposure in the Navy

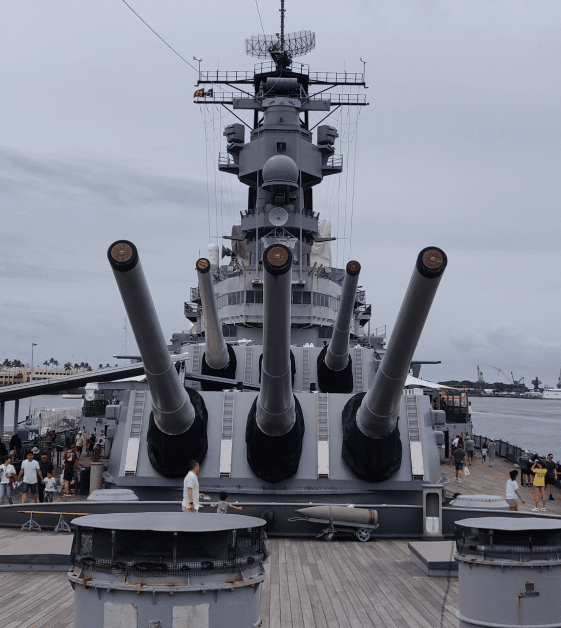

Many Navy veterans were exposed to asbestos, particularly in Navy ships. Many products that contain asbestos were used in boilers, engine rooms, and pipes, among others, to improve a ship’s fireproofing and seaworthiness. This resulted in many potential sources of exposure to asbestos fibers, which are the main cause of mesothelioma.

Home » National Mesothelioma Law Firm » Veterans » Military Asbestos Exposure » Asbestos Exposure in the Navy

Navy Occupations with the Highest Asbestos Exposure Levels

Asbestos Exposure in Naval Shipyards

Asbestos in the Navy During World War II

Did the Navy Know Asbestos Was Hazardous to Human Health?

Can You Sue the Navy for Asbestos Exposure?

The Lanier Law Firms Helps Navy Veterans Recover Substantial Compensation

Military veterans account for nearly a third of all mesothelioma cases in the United States, and Navy veterans experienced the most extensive asbestos exposure during military service. As a result, they face a heightened risk of developing mesothelioma, asbestosis, and lung cancer.

Asbestos-related illnesses are painful diseases that shorten life expectancy. These diseases generally develop 20, 30, 40, or more years after the initial exposure. As a result, Navy veterans who served our country during World War II, Vietnam, and the Gulf War are still being diagnosed with mesothelioma today.

Navy Occupations with the Highest Asbestos Exposure Levels

Navy veterans have faced occupational asbestos exposure while serving in the following capacities:

- Gunner’s mate

- Electrician’s mate

- Hull maintenance technician

- Machinist

- Firefighter

- Welder

- Pipefitter, steamfitter, and plumber

- Boat and engine mechanic

Asbestos Use on Navy Ships

The highest risk of asbestos exposure in the Navy occurred aboard Navy ships and in shipyards. Asbestos was used heavily on Navy ships due to its ability to insulate against heat, water, and corrosion. It was used in plumbing fixtures, adhesives, industrial compounds, cabin insulation, the mechanical parts of ships, and the hull. It was common for the entire hull of Navy ships to be lined with asbestos.

Asbestos was used on Navy ships beginning in the 1880s and was not completely eliminated until approximately 1985. The Navy required its use, and even safety organizations such as the National Fire Protection Association and the National Board of Fire Underwriters required it as a fire safety measure.

Ship Components that Contained Asbestos

Nearly every component on Navy ships contained asbestos. There was virtually nowhere a sailor could go on a ship where asbestos was absent.

How Were Sailors Exposed to Asbestos on Navy Ships?

The vibration and constant motion of ships at sea caused components to flake and crack more quickly than if they were in stable structures on land. This included ship parts containing asbestos.

Sailors that performed routine maintenance and repairs on engines and other mechanical ship components experienced the highest levels of asbestos exposure.

When Did the Navy Stop Using Asbestos on Ships?

While asbestos use was largely eliminated between 1975 and 1978, it was not strictly prohibited. Ships constructed until 1980—and even after 1985—possibly contain asbestos. The Navy is still permitted to use asbestos if it deems no suitable alternative is available.

Do Navy Ships Still Contain Asbestos Today?

Testing is the only definitive way to know if a specific ship contains asbestos. Some older ships are still in service, and asbestos may still be present on these ships.

Asbestos Exposure in Naval Shipyards

Naval shipyard workers directly handle asbestos and the components that contain it. They may be tasked with complete rip-outs of hulls, gaskets, and other components with significant asbestos levels.

Measurements taken from the Long Beach Naval Shipyard during removal operations showed an average asbestos level of 40 to 150 fibers per cubic centimeter. In a 1964 Occupational Health Hazard report, researchers observed the following:

By far, the greatest potential exposure to asbestos fibers occurs during ripout of old insulation for ship overhaul or reconversions.

The report noted pipe coverers wore protection, but nearby workers did not. These workers experienced what is known as bystander exposure. Insulation shop workers in shipyards were exposed to asbestos during insulation installation and removal.

In the pipe covering shops, workers were exposed to asbestos during the following processes, resulting in bystander asbestos exposure throughout the work areas:

- Cutting hard pieces of asbestos with band saws

- Manufacturing asbestos pipe covering

- Cutting and pounding asbestos matting

Shipyard workers experienced asbestos exposure during installation, repair, and routine maintenance of engine parts, brakes, the ship hull, wallboards, and plumbing pipes. They were exposed to asbestos while installing or otherwise working with wiring, adhesives, and industrial compounds.

Asbestos exposure during shipbuilding primarily occurred until the late 1970s, but asbestos exposure may still occur during repairs and rip-outs involving older ships.

Asbestos in the Navy During World War II

During World War II, the Navy began stockpiling chrysotile, crocidolite, and various grades of amosite asbestos to such an extent that civilian use was prohibited to conserve the material for the war effort. It was used freely on sea vessels, land machinery, weaponry, and even personal protective gear in need of its fire-protective properties.

Learn More About

Filing a Mesothelioma Lawsuit

- Are you eligible?

- What is the average settlement?

- How long will it take?

Why Should You Trust the Lanier Law Firm to Handle your Mesothelioma Case?

Did the Navy Know Asbestos Was Hazardous to Human Health?

The Navy was at the forefront of asbestos research and became aware of its dangers by the 1930s. In fact, it was one of the most knowledgeable agencies in the world regarding asbestos. By all accounts, the Navy knew it was a severe occupational hazard but believed it could be controlled with proper handling. Consequently, it began recommending and requiring exposure protection by 1939.

These precautions included the following:

- Wetting down asbestos materials to prevent dust

- Requiring certain workers to wear respirators

- Providing protective gloves

Where respirators were impractical aboard ships, the navy recommended keeping amosite asbestos wet at all times to prevent dust.

Despite its awareness of the dangerous aspects of asbestos, the Navy did not relay this information to the sailors or its commanding officers until 1962, when it distributed a publication on how to avoid asbestosis.

However, this publication fell short of providing workers with the full extent of the danger they faced regarding asbestos hazards. At the time, it was erroneously believed that only long asbestos fibers were dangerous and that asbestos dust was inert. It is now widely known that even the smallest particle of asbestos can lead to mesothelioma.

Did the Navy Do Enough to Protect Workers?

While wetting asbestos and utilizing personal protective equipment are important protective measures when handling asbestos, these actions alone are known to be inadequate by today’s standards. Asbestos abatement professionals adhere to the following protocols in addition to the Navy’s:

- Containment: Use plastic sheeting to tightly seal the contaminated area. Disposal: Dispose of asbestos material in 6 mm double plastic bags and place it in EPA-approved dumpsters.

- Purification: Clean the air using HEPA filtration equipment.

- Testing: Test the air regularly throughout and after the work.

- Decontamination: Require asbestos workers to decontaminate before leaving the concealed area.

- Disposable clothing: Wear disposable gloves and clothing throughout the work.

OSHA requires similar practices in workplaces where asbestos materials are handled. Under OSHA regulations, any areas known to contain asbestos must be clearly marked. Access to these areas is restricted, and employees who enter these areas are prohibited from eating, drinking, chewing gum, or applying cosmetics.

The Navy only required workers directly handling asbestos to wear protection, and the asbestos was never contained. Nearby workers were completely unprotected, and asbestos fibers were allowed to move freely around ships, shipyards, and other workplaces through the environment and on work uniforms.

Navy Veterans and Mesothelioma

These practices were clearly insufficient to protect workers and prevent the spread of asbestos fibers. Based on the number of mesothelioma cases affecting Navy veterans, the U.S. Navy did not do enough.

Approximately 30 percent of malignant pleural mesothelioma cases occur in military veterans. The Environmental Working Group estimates that as many as 40,000 veterans have died of asbestos-related illnesses. The majority of these asbestos-exposure victims served in the Navy.

Can You Sue the Navy for Asbestos Exposure?

The Feres Doctrine bars lawsuits against the military for injuries or illnesses sustained while serving on active duty. However, this does not eliminate the possibility of mesothelioma compensation for Navy veterans.

While there is no specific Navy asbestos settlement, you may be able to sue the asbestos companies that supplied asbestos to the Navy under the doctrine of strict liability. Companies that supplied asbestos to the military include the following:

- Johns-Manville

- John Crane

- Coltec Industries, the former parent company of Garlock Sealing Technologies Inc.

- Armstrong International

- Flexitallic

Some of these companies have declared bankruptcy. These companies cannot be sued but have established asbestos trust funds under Section 524(g) of the U.S. Bankruptcy Code. Navy veterans with mesothelioma may be able to file trust fund claims against these companies, which include the following:

- Armstrong World Industries

- Flexitallic

- Garlock Sealing Technologies, Inc.

- Johns-Manville

Eligible Navy veterans with asbestos-related illnesses can also file a claim for veterans’ benefits. When you file a VA mesothelioma claim, you may be able to receive monthly tax-free monetary benefits and free medical care. Compensation may be payable via VA disability benefits, pensions, and the Aid and Attendance program.

VA benefits are also available for the families of Navy veterans who have passed away due to asbestos exposure in the military. In addition, the family members of veterans who have passed away may be able to file trust fund claims and wrongful death lawsuits against the responsible companies.

The Lanier Law Firm Helps Navy Veterans Recover Substantial Compensation for Mesothelioma

Our experienced and compassionate mesothelioma lawyers have a consistent track record of obtaining outstanding case results for asbestos-related illnesses on behalf of Navy personnel and shipyard workers, such as the following:

- $3.7 million for an 82-year-old man exposed to asbestos in the Navy

- $2.3 million settlement for a California man exposed to asbestos at a naval shipyard

- $2 million settlement for a former shipyard worker diagnosed with pleural mesothelioma

- $1.9 million settlement for the family of a deceased chief engineer who was exposed to asbestos in the engine rooms of cruise ships

By submitting this form, you agree to our terms & conditions. Please read full disclaimer here.